Customers want right-sized, recyclable packaging that minimises waste and ensures damage-free delivery, which is why Amazon aims to avoid unnecessary packaging whenever possible. When this is not an option, we optimise the type, material, and weight of our packaging to increase circularity, avoid waste, and reduce carbon emissions—without sacrificing safety or functionality.

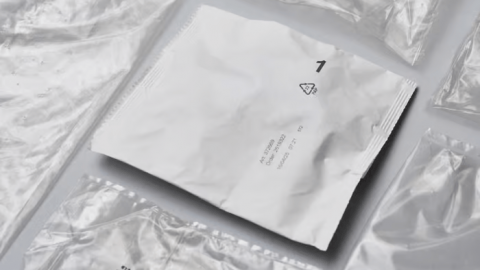

As part of this commitment, our packaging scientists and engineers, alongside Mondi, have developed a new paper-padded envelope with shock-absorbent, paper-based lining that protects deliveries without using any plastic content—unlike envelopes lined with bubble wrap which had been used previously.

This latest design is simple and effective, and designed to keep products securely in place, while simultaneously absorbing stress put on the package during its journey to a customer’s home. Due to the lightweight lining, the package itself is much lighter than equivalent-sized cardboard boxes, avoiding 44g of packaging per shipment, on average. They are also easy to fill without wasted space due to their greater flexibility, and the fact they don’t require additional padding materials to be added. Amazon’s European padded-padded envelope was recognised as the best ‘E-commerce’ packaging at the 2024 Packaging Europe Sustainability Awards. The innovative packaging solution also won best packaging in the recycling category of the 2024 ALL4PACK Innovation Awards